The

house is currently in the design and fund raising stage.

We are working with TLC Engineering on the design of the

house to achieve the Platinum level of accreditation. This

level of accreditation is only held by 15 other buildings

in the world. None of these buildings are under the most

current version of the requirements. FSU and ESC would

like to be the first to achieve this achievement in

Florida, setting the standard for FSU and bringing

exposure to our area in the fields of engineering and

environmentally friendly development. Not only are we

showing a consciousness in this field but we are striving

to be the best. We are in a hold due to funding at the

moment but ESC along with FSU Foundation and key

influential people in our community are working to rectify

this problem. Stay tuned for further updates.

The

house is currently in the design and fund raising stage.

We are working with TLC Engineering on the design of the

house to achieve the Platinum level of accreditation. This

level of accreditation is only held by 15 other buildings

in the world. None of these buildings are under the most

current version of the requirements. FSU and ESC would

like to be the first to achieve this achievement in

Florida, setting the standard for FSU and bringing

exposure to our area in the fields of engineering and

environmentally friendly development. Not only are we

showing a consciousness in this field but we are striving

to be the best. We are in a hold due to funding at the

moment but ESC along with FSU Foundation and key

influential people in our community are working to rectify

this problem. Stay tuned for further updates.

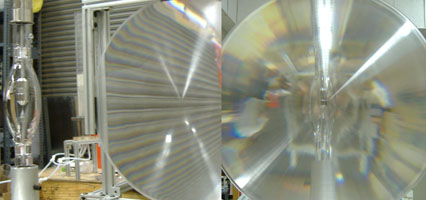

The solar-thermal tri-generation system is

designed to address the high-energy costs associated with

power production, refrigeration, and heating in lesser

developed areas or emergency situations. Our system at ESC

is currently in the testing process for power generation,

refrigeration, and water heating; it consists of a

concentrating solar concentrator and a thermal receiver.

The solar concentrator is of the parabolic dish type,

which is covered with a reflective aluminized mylar. This

focuses the sun’s rays onto the receiver mounted at the

focal point of the concentrator. The extreme temperatures

created at the focal region, in excess of 650C, is then

transferred by the receiver to heat a circulating fluid,

which is then transported elsewhere for various thermal

uses. For power production, the working fluid is water,

which is flashed to steam. This high-temperature,

high-pressure steam is then expanded through a small

high-speed turbine coupled with a generator for electric

power production. The exhaust steam is then condensed

before reentering the system so as to minimize working

fluid losses and increase system efficiency by preheating

the working fluid. For refrigeration and water heating, an

ethylene-glycol mixture is used. The ethylene-glycol

mixture is used as a thermal transport medium to transfer

the heat from the receiver to a thermal reservoir. For

refrigeration, the thermal reservoir is used in

conjunction with an anhydrous-ammonia refrigeration cycle.

This cycle is similar to the conventional refrigeration

cycle, however, instead of the refrigerant being

compressed by the work of a shaft from an electric

compressor, it is pressure driven by the addition of heat,

thus making off-grid refrigeration plausible. For water

heating, a heat exchanger is used in the thermal storage

reservoir. Instead of water being heated by an electric

heating element, the heat will be transferred from the

thermal reservoir to the water. Ideally, all three

components for the system will be able to operate

simultaneously for tri-generation in areas where off-grid

availability is essential.

The solar-thermal tri-generation system is

designed to address the high-energy costs associated with

power production, refrigeration, and heating in lesser

developed areas or emergency situations. Our system at ESC

is currently in the testing process for power generation,

refrigeration, and water heating; it consists of a

concentrating solar concentrator and a thermal receiver.

The solar concentrator is of the parabolic dish type,

which is covered with a reflective aluminized mylar. This

focuses the sun’s rays onto the receiver mounted at the

focal point of the concentrator. The extreme temperatures

created at the focal region, in excess of 650C, is then

transferred by the receiver to heat a circulating fluid,

which is then transported elsewhere for various thermal

uses. For power production, the working fluid is water,

which is flashed to steam. This high-temperature,

high-pressure steam is then expanded through a small

high-speed turbine coupled with a generator for electric

power production. The exhaust steam is then condensed

before reentering the system so as to minimize working

fluid losses and increase system efficiency by preheating

the working fluid. For refrigeration and water heating, an

ethylene-glycol mixture is used. The ethylene-glycol

mixture is used as a thermal transport medium to transfer

the heat from the receiver to a thermal reservoir. For

refrigeration, the thermal reservoir is used in

conjunction with an anhydrous-ammonia refrigeration cycle.

This cycle is similar to the conventional refrigeration

cycle, however, instead of the refrigerant being

compressed by the work of a shaft from an electric

compressor, it is pressure driven by the addition of heat,

thus making off-grid refrigeration plausible. For water

heating, a heat exchanger is used in the thermal storage

reservoir. Instead of water being heated by an electric

heating element, the heat will be transferred from the

thermal reservoir to the water. Ideally, all three

components for the system will be able to operate

simultaneously for tri-generation in areas where off-grid

availability is essential.

Solar radiation can be divided into direct beam radiation, diffuse radiation and reflected radiation. Concentrated Solar Power (CSP) applications can only collect the direct beam radiation. CSP includes parabolic troughs; parabolic dishes or heliostats. A Pyrheliometer is used to measure the direct beam radiation from the sun. The efficiency of the solar power plant can then be determined knowing the incoming direct beam radiation from the sun.

Pyrheliometers on the market today are extremely expensive making accurate CSP site data collection cost prohibitive. An affordable pyrheliometer would increase the ability for proper site selection and optimal design of a CSP system for specific sites. ESC is designing and implementing an affordable pyrheliometer that will provide the important data, allowing engineers to make better decisions when designing CSP applications.

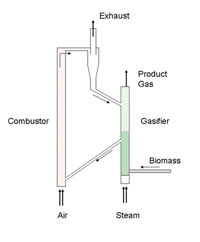

Biomass is a sustainable energy

source that has been used for thousands of years. New

technologies provide a way harness this energy source more

efficiently and cleaner than ever before. Biomass

gasification is the process of converting biomass, like

woodchips, sawdust, switch grass etc., to a usable gaseous

fuel. Conventional downdraft gasifiers produce a low

energy gas that is not suitable for storage or

transportation. By using a dual fluidized bed type

gasifier, a medium grade gas can be produced that is rich

in H2. As the figure shows, dual fluidized beds separate

the combustion products from the gasification products

leading to a much higher quality product gas. The product

can be used for power generation, conversion to liquid

fuel or H2 production. This type of gasification can

provide a sustainable path to producing H2 for new and

exciting technologies. Research being performed at ESC

will take this technology one step closer to mainstream

implementation.

Biomass is a sustainable energy

source that has been used for thousands of years. New

technologies provide a way harness this energy source more

efficiently and cleaner than ever before. Biomass

gasification is the process of converting biomass, like

woodchips, sawdust, switch grass etc., to a usable gaseous

fuel. Conventional downdraft gasifiers produce a low

energy gas that is not suitable for storage or

transportation. By using a dual fluidized bed type

gasifier, a medium grade gas can be produced that is rich

in H2. As the figure shows, dual fluidized beds separate

the combustion products from the gasification products

leading to a much higher quality product gas. The product

can be used for power generation, conversion to liquid

fuel or H2 production. This type of gasification can

provide a sustainable path to producing H2 for new and

exciting technologies. Research being performed at ESC

will take this technology one step closer to mainstream

implementation.

A solar simulator

allows us to test solar systems independent from current

weather conditions and time of day. This means that solar

research can happen at an accelerated rate because of the

amount of time able to study a system with constant

testing conditions. The simulator creates artificial

sunlight using xenon-arc lamps. These lamps produce

similar quality light to that of the sun. With the help of

a Fresnel lens, this light is made into direct beam

radiation with intensity of about 1 sun. By making direct

beams of light we are able to test systems that

concentrate sunlight as well as those that do not. The

lights are arranged in an array to produce a large area

for testing. This area is adjustable by adding or

subtracting lights and lens but is ultimately limited by

the size of the room.

A solar simulator

allows us to test solar systems independent from current

weather conditions and time of day. This means that solar

research can happen at an accelerated rate because of the

amount of time able to study a system with constant

testing conditions. The simulator creates artificial

sunlight using xenon-arc lamps. These lamps produce

similar quality light to that of the sun. With the help of

a Fresnel lens, this light is made into direct beam

radiation with intensity of about 1 sun. By making direct

beams of light we are able to test systems that

concentrate sunlight as well as those that do not. The

lights are arranged in an array to produce a large area

for testing. This area is adjustable by adding or

subtracting lights and lens but is ultimately limited by

the size of the room.

A

significant hurdle to the implementation of a

hydrogen-based economy is the fact that hydrogen cannot be

made at an economically feasible price. It is widely

speculated that water electrolysis, which separates water

into its component elements of hydrogen and oxygen, will

be the means of generating hydrogen in this type of

economy. Water electrolysis systems (electrolyzers)

currently employ either platinum or nickel-based alloy

electrodes, which can account for up to 80% of the cost of

a commercial electrolyzer. Based on an analysis of the

Photosystem II process, which is widely observed in

nature, thin metal oxide films have been developed in the

laboratory at FSU for the purpose of improving water

electrolysis. These films have demonstrated the ability to

generate both hydrogen and oxygen near their thermodynamic

limits, thus allowing for efficiencies above 99%.

A

significant hurdle to the implementation of a

hydrogen-based economy is the fact that hydrogen cannot be

made at an economically feasible price. It is widely

speculated that water electrolysis, which separates water

into its component elements of hydrogen and oxygen, will

be the means of generating hydrogen in this type of

economy. Water electrolysis systems (electrolyzers)

currently employ either platinum or nickel-based alloy

electrodes, which can account for up to 80% of the cost of

a commercial electrolyzer. Based on an analysis of the

Photosystem II process, which is widely observed in

nature, thin metal oxide films have been developed in the

laboratory at FSU for the purpose of improving water

electrolysis. These films have demonstrated the ability to

generate both hydrogen and oxygen near their thermodynamic

limits, thus allowing for efficiencies above 99%.

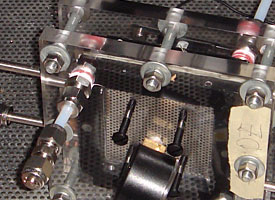

PEM fuel cells have the

benefits of quick start-up and relatively low temperature

operation, which make them the most likely candidates for

use in automobile and home applications. In order for

these fuel cells to achieve widespread adoption a number

of engineering challenges must be overcome. Two of these

challenges, the even distribution of hydrogen and air

across the membrane and the need for active cooling of the

fuel cell, are being addressed by the PEM fuel cell

research at ESC. A prototype of a novel fuel cell design

has been built and preliminary testing has yielded

promising results.

PEM fuel cells have the

benefits of quick start-up and relatively low temperature

operation, which make them the most likely candidates for

use in automobile and home applications. In order for

these fuel cells to achieve widespread adoption a number

of engineering challenges must be overcome. Two of these

challenges, the even distribution of hydrogen and air

across the membrane and the need for active cooling of the

fuel cell, are being addressed by the PEM fuel cell

research at ESC. A prototype of a novel fuel cell design

has been built and preliminary testing has yielded

promising results.

In conjunction with the electrolysis development, research

is also ongoing into the use of non-platinum catalysts.